This is a short overview of the components used to make yourself a remote controlled car using a PIC32 microcontroller.

Have you ever wanted to make and control your own car, see below for the components used. In the future I will go over an in depth tutorial with schematics of the connections.

Items used:

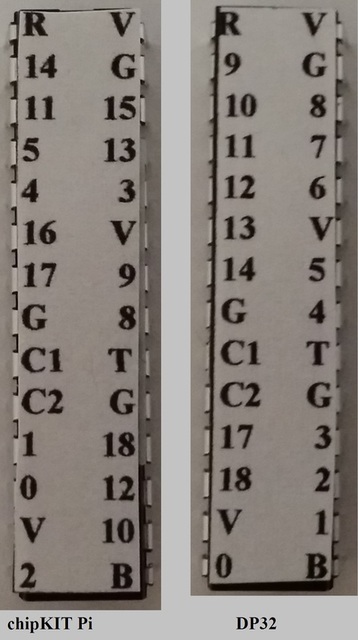

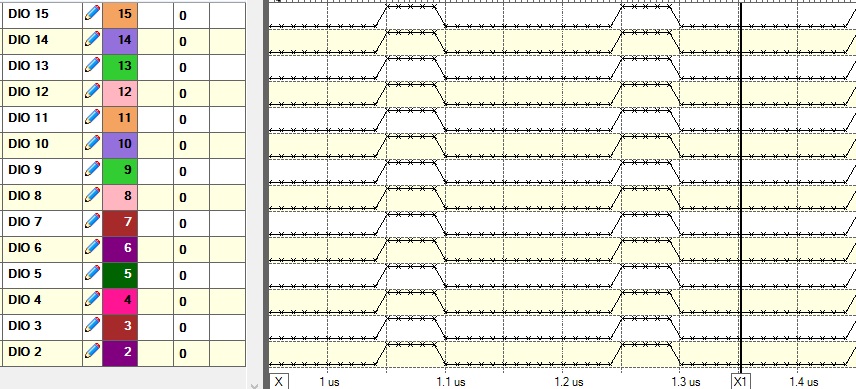

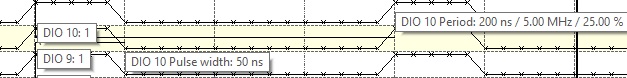

Most of the items used I found on eBay for fairly cheap. The power source I used was a 5 volt 10,000 mAh power bank that was then boosted to 6 volts using the step-up module which would power the car for several hours of fun. Seen in the video and photos I used my MAKEmicro32 microcontroller board seen plugged in the breadboard.

See my contact page to request the code I used or if you would like me to put together the in depth tutorial with schematics for a guide to connect everything together.

Have you ever wanted to make and control your own car, see below for the components used. In the future I will go over an in depth tutorial with schematics of the connections.

Items used:

- PIC32 microcontroller

- Power source

- L293D Push-Pull 4-Channel Driver

- XL6009 Step-up module

- Four Arduino wheels

- Breadboard

- Several jumper wires

- Some rubber bands

- Some cardboard

- My PIC32BTN Android application

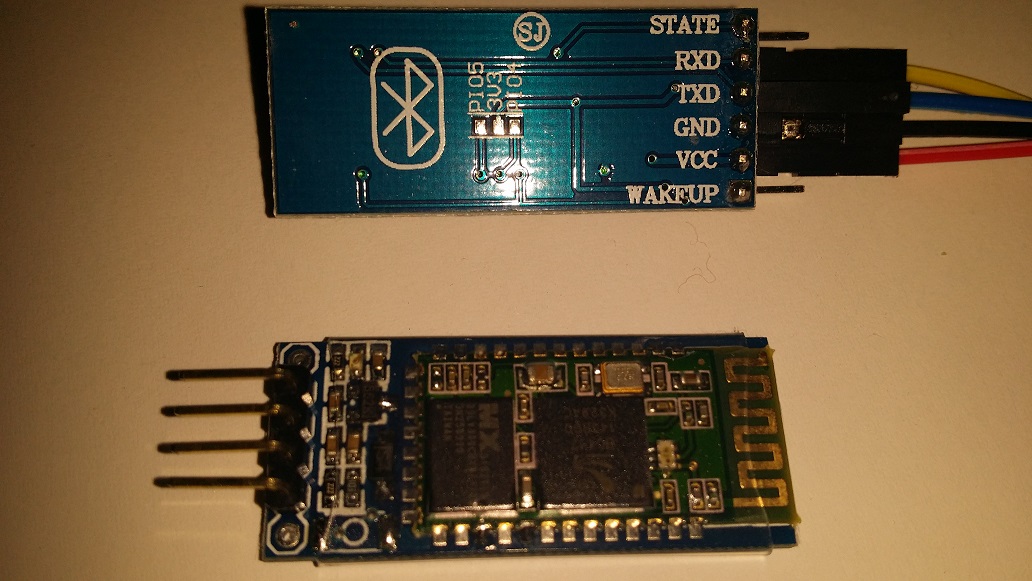

- HC-05 Bluetooth Module

Most of the items used I found on eBay for fairly cheap. The power source I used was a 5 volt 10,000 mAh power bank that was then boosted to 6 volts using the step-up module which would power the car for several hours of fun. Seen in the video and photos I used my MAKEmicro32 microcontroller board seen plugged in the breadboard.

See my contact page to request the code I used or if you would like me to put together the in depth tutorial with schematics for a guide to connect everything together.

RSS Feed

RSS Feed